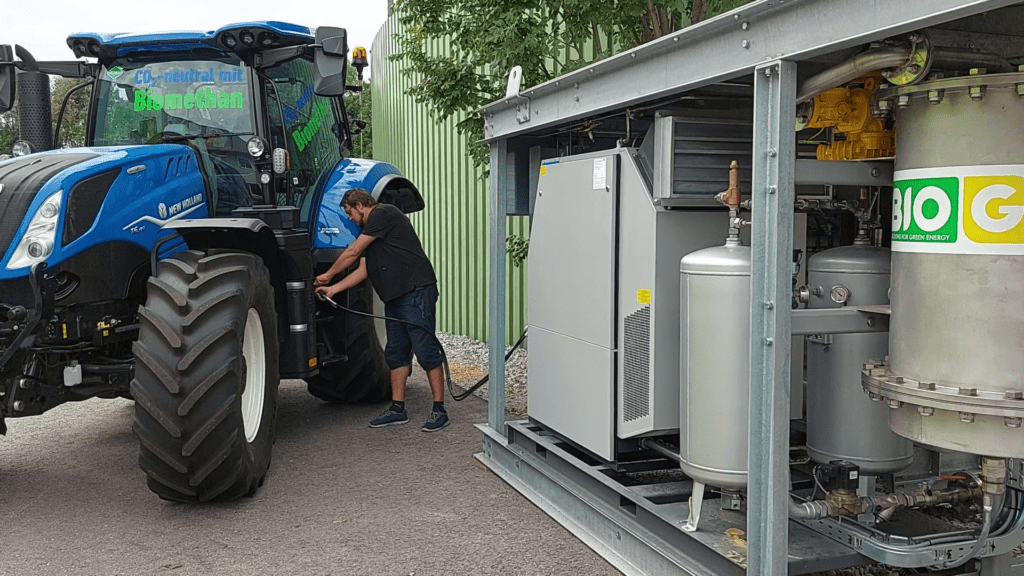

Produisez votre propre carburant et obtenez des certificats ges grâce à votre station-service.

Le GNV est du Biogaz purifié, comprimé à 250 bars. Il est utilisé pour tout type véhicules fonctionnant au gaz naturel.

Produisez votre propre carburant et obtenez des certificats ges grâce à votre station-service.

Le GNV est du Biogaz purifié, comprimé à 250 bars. Il est utilisé pour tout type véhicules fonctionnant au gaz naturel.

Elle fonctionne de la façon suivante:

10 à 20 % de votre production de Biogaz est prélevé de votre production; il est ensuite nettoyé, comprimé et séparé de son CO2 via une épuration membranaire. Le CH4 obtenu est ensuite comprimé à 250 bars et stocké dans des bouteilles. Le GNV est donc disponible dans les bouteilles pour les véhicules. Les OFF-gaz, 82 % de CO2 ET 18 % de CH4, sont directement renvoyés dans la ligne d’alimentation du moteur de cogénération.

3 tailles: 35, 65 et 100 m³ de Biogaz

TYPE 3 niveaux |

T35D |

T65D |

T100D |

| Quantité de biogaz m³/h | 27,3 | 50,4 | 77,5 |

| Nombre de membranes | 3 | 3 | 3 |

| CH4 m3/h à 52 % CH4 | 14,2 | 26,2 | 40,3 |

| CH4 dans les gaz résiduaires à 0,5 % m³ | 0,07 | 0,13 | 0,20 |

| CH4 m3/h pour le GNC | 14,1 | 26,1 | 40,1 |

| GNC kg/h 97 % CH4 | 10,4 | 19,3 | 29,6 |

| GNC kg/jour | 250 | 462 | 711 |

| GNC kg/an | 91 462 | 168 786 | 259 645 |

| Diesel l/an | 118 900 | 219 420 | 337 538 |