As experts for the introduction of organic substrates into biogas plants, we are also specialized in planning and integrating the right pumping technology for biogas plants. Pumps are mainly used in the form of mixing pumps. If very dry, organic substrates are fed, separation occurs in the fermenter. This can be avoided by the forced mixing of solid and liquid materials with a mixing pump.

WANGEN BIO-MIX

The WANGEN BIO-MIX pumps have been integrated into the energy production process for years and have been continuously further developed and optimized ever since. They are suitable for conveying corn silage, grass silage, whole plant silage, solid manure, chicken manure, waste and co-ferments that are mixed with liquid materials in the pump.

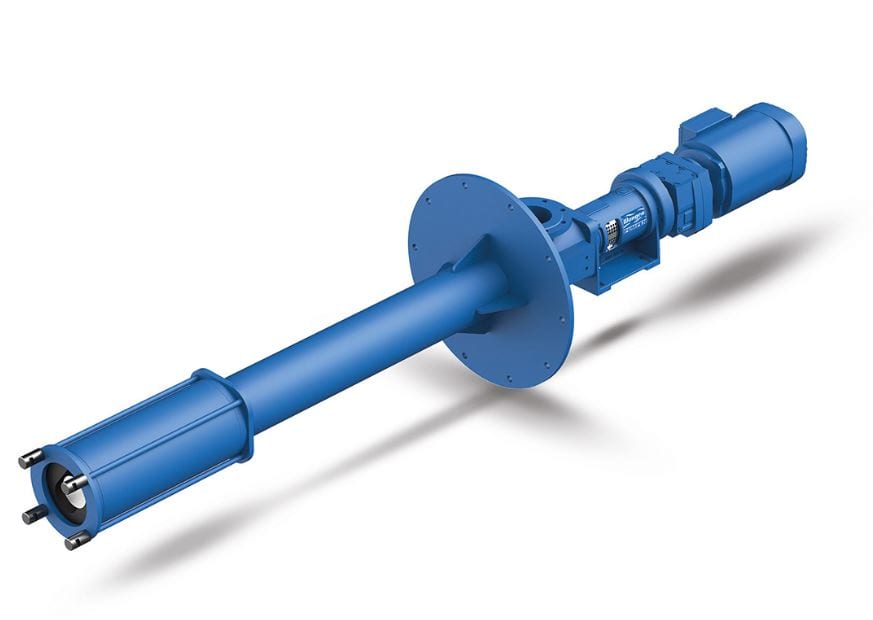

Suction pump (feed pump)

The WANGEN type KL-S helical rotor pump with its bearing bracket belongs to the basic product group of the pump factory. The central advantage of the pump concept lies in the low life cycle costs. The universally applicable pump is suitable for pumping almost all low to extremely high viscosity media (1 mPas -3,000,000 mPas).

Submersible pump (type KL-T)

The WANGEN type KL-T helical rotor pump is suitable as a submersible pump for pumping materials from tanks and containers. The pumped materials – regardless of whether they are liquid, abrasive, lumpy, sticky or highly viscous – are conveyed gently and without impairing the structure and the quality of the product.

WANGEN XPRESS

Replacement of wearing parts in a few simple steps, without dismantling the pump from the piping system thanks to the Service in Place. The Xpress pump series has been specially developed to shorten service times and thus reduce costs. The X-LIFT quick-change system developed by WANGEN PUMPEN ensures reliable pumping of the media as well as fast rotor/stator changes.