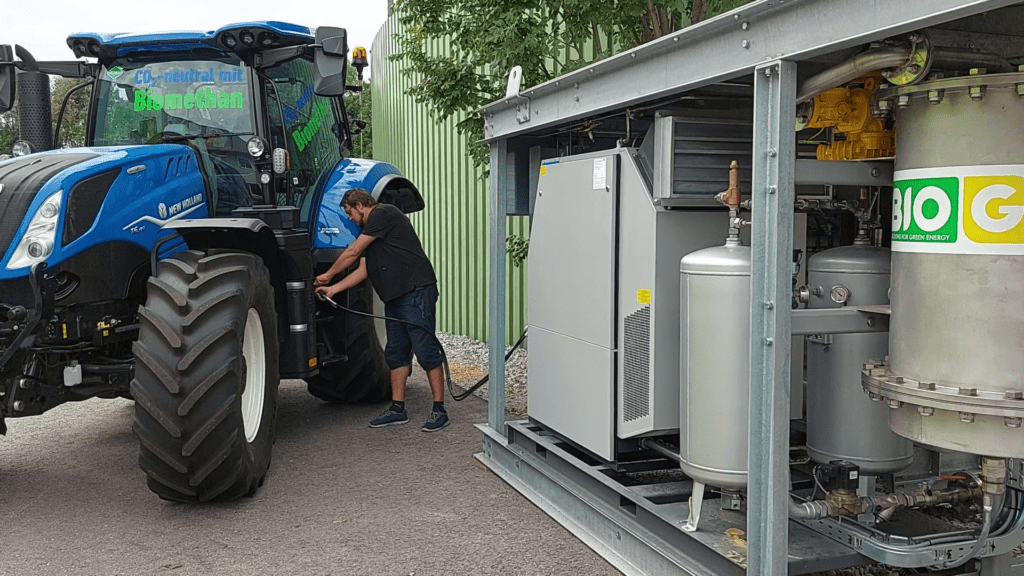

Produce fuel now with your own farm filling station and secure GHG certificates.

BioCNG is purified biogas that is compressed to 250 bar. This is used for all commercially available CNG vehicles.

Produce fuel now with your own farm filling station and secure GHG certificates.

BioCNG is purified biogas that is compressed to 250 bar. This is used for all commercially available CNG vehicles.

And this is how it works:

The BioG farm filling station was developed for partial flow fuel production in biogas plants. A partial flow of approx. 10% – 20% of the biogas produced is removed from the process – purified – compressed – CH4 is separated from the CO2 via a membrane – highly compressed to 250 bar – stored in storage cylinders – and delivered as fuel to CNG vehicles. The Offgas with approx. 82 % CO2 and approx. 18 % CH4 is fed back into the gas stream to the biogas engine.

Size: 35, 65 or 100 m³ biogas/h

TYP Three Stage membrane separation |

T35D |

T65D |

T100D |

| Biogas quantity m³/h | 27,3 | 50,4 | 77,5 |

| Number of membranes | 3 | 3 | 3 |

| CH4 m3/h at 52 % CH4 | 14,2 | 26,2 | 40,3 |

| CH4 in offgas at 0.5% m³ | 0,07 | 0,13 | 0,20 |

| CH4 m³/h for CNG | 14,1 | 26,1 | 40,1 |

| CNG kg/h 97 % CH4 | 10,4 | 19,3 | 29,6 |

| CNG kg/day | 250 | 462 | 711 |

| CNG kg/year | 91 462 | 168 786 | 259 645 |

| Diesel l/year | 118 900 | 219 420 | 337 538 |